Polystyrene compactor helps to change the circular economy in Spain

Do you use a porexpan? I think almost everyone's answer is yes. Hundreds of thousands of foam products are produced every year, and from food containers to courier packaging, foam materials are indispensable in everyday life. But do you know what happens when polystyrene is removed? The answer to this question is bound to be controversial. Some believe that polystyrene is not recyclable and should be sent directly to landfill or incinerators, while others believe that polystyrene can be processed by professional recycling teams, ultimately creating a closed recycling loop.

Indeed, this polarisation is not surprising. After all, the benefits of polystyrene are well known, otherwise it wouldn't be widely used in all aspects of our lives. But there are still many people who are unaware that styrofoam can be recycled, and the difficulty of recycling is a reality that we must face directly. The latest Cotec circular economy report reflects that Spain's transition to a circular economy has stalled in the last five years, despite the implementation of different policies and strategies and the growing awareness of citizens of the concept. Spain's recycling rate of 35% is far from the 50% target set by the European Commission for 2020. With regard to waste disposal, the

If EPS waste ended up in landfills, it would take up valuable earth resources for centuries. Fortunately, the arrival of the polystyrene compactor has helped to solve the aforementioned problems of low recovery rates and high waste accumulation rates in Spain. Its magic lies in its ability to completely recycle polystyrene waste. The EPS waste is placed in the hopper of the XPS foam compactor and the machine crushes and removes 98% of the air from the waste. The cold briquettes compressed by the screw are granulated and finally made into framed products for sale.

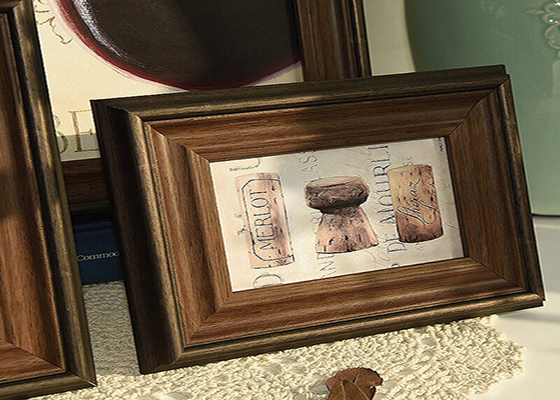

No one would ever associate a beautiful picture frame in a shopping mall with foam waste and not believe that they are the same material. The polystyrene compactor is the perfect recycling system from compression to pelletizing. Plastic pellets made from the recyclable raw material EPS are not only more environmentally friendly, but also more resistant to moisture and insects than wooden frames. With improved recycling equipment and processes, the perception of foams such as polystyrene will change from being a source of environmental pollution to an environmentally friendly material. Spain's circular economy is in desperate need of transformation and the polystyrene recycling team because the Styrofoam compactor is certainly the icing on the cake for it.