Foam plastic is widely used in packaging,agricultural, home, auto and electronic industries and varies from different characteristics.

Foam plastic is bulky and takes up a lot of space, foam compacting technology is aimed to reduce its volume and facilitate to transport and reuse.

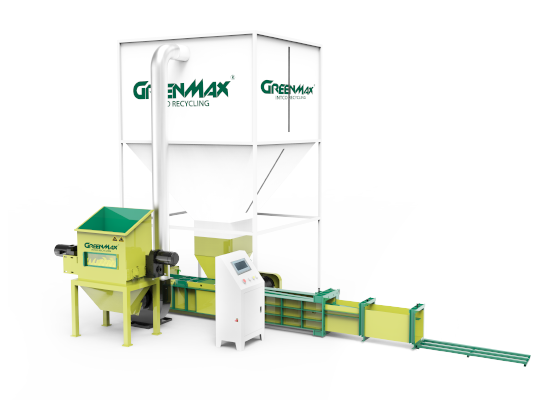

GREENMAX designed different series to deal with all kinds of foam materials and reach different compression ratio.

Foam Melter: Compression ratio up to 90:1

Foam Cold Compactor: compression ratio up to 50:1

Hydraulic Compactor: compression ratio up to 70:1

Greenmax foam hydraulic compactor with stronger compacting power is designed to handle rigid plastic with low viscosity.

> ADVANTAGE:

> 5 to 2 times than screw on compression density

> simplicity of operator and easy to use

> lower risk of melting

> TECHNICAL DATA:

ITEM: H-C300

Total Power Consumption: 24.5kw

Hydraulic Press Power: 11kw

Feeder Power: 11kw

Crusher Power: 2*4kw

Blower Power: 5.5kw

Production Capacity: 200kg/h-300kg/h (depends on materials)

EPS Compression Density: 300-380kg/mmm(depends on materials)

EPS Compression Dimension: 390*420(w/h)mm

Feed Hopper Door: 1200*800(l/w)mm

Square Meters: 8162*4355*4430(l/w/h)mm

Weight: Approximately 3500kg

|

If you want to know more information, please leave us a message and we will contact you as soon as possible! |

GREENMAX ZEUS Series Densifier

GREENMAX ZEUS Series Densifier