The EPS foam recycling system is a large weight EPS recycling machine introduced at the end of GRENMAX 2022. Distinguished from the previous single machine, it is a large EPS recycling machine dedicated to the recycling of EPS beads, which can also be referred to as an EPS recycling system. The integrated system provides a more comprehensive recovery of EPS foam than a single machine.

Why use an EPS recovery system?

1. New EPS is an expensive material and adding recycled material helps to reduce production costs

2. EPS is 100% recyclable, so using an EPS recycling system will reduce your environmental impact.

3. The use of recycled materials in plastic products is promoted globally and is in line with the ESG philosophy.

4. EPS recycling systems make it possible to turn EPS scrap into waste and pollution-free.

System recycling process

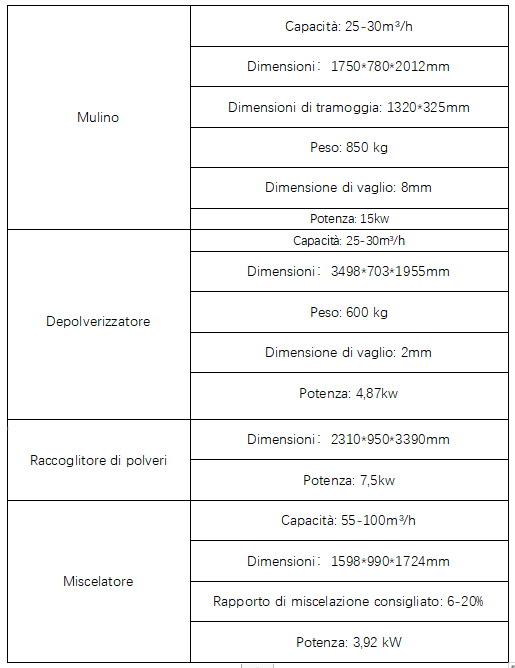

PHASE 1 Mill completes the shredding of the waste material

The EPS scrap is fed into the shredder of the EPS recycling system to obtain EPS scrap. The material obtained in this step contains reusable and non-reusable EPS beads which are mixed and separated in a subsequent screening operation.

PHASE 2 dust collector completes the bead sieving operation

After mixing, the EPS beads are sorted by the dust extraction unit of the EPS recycling system. This unit is equipped with a special screen for sorting the pearls.

After screening, the reusable EPS beads are separated more precisely from the non-reusable beads. The reusable beads are introduced into the mixer and the final bin, while the non-reusable beads are collected in the collection unit and are not involved in further handling processes.

PHASE 3 Mixing of new and recycled materials

After the screening process, the reusable EPS beads enter the Final Silo, which is located at the end of the EPS recycling system and is divided into two parts, one for the recycled EPS beads we obtain and the other for the new EPS material, which is mixed with the recycled pearls.