Can polyethylene recycling be environmentally friendly?

The answer is yes! This is probably one of the most important properties of polyethylene, as it can have a huge potential impact on the environment.

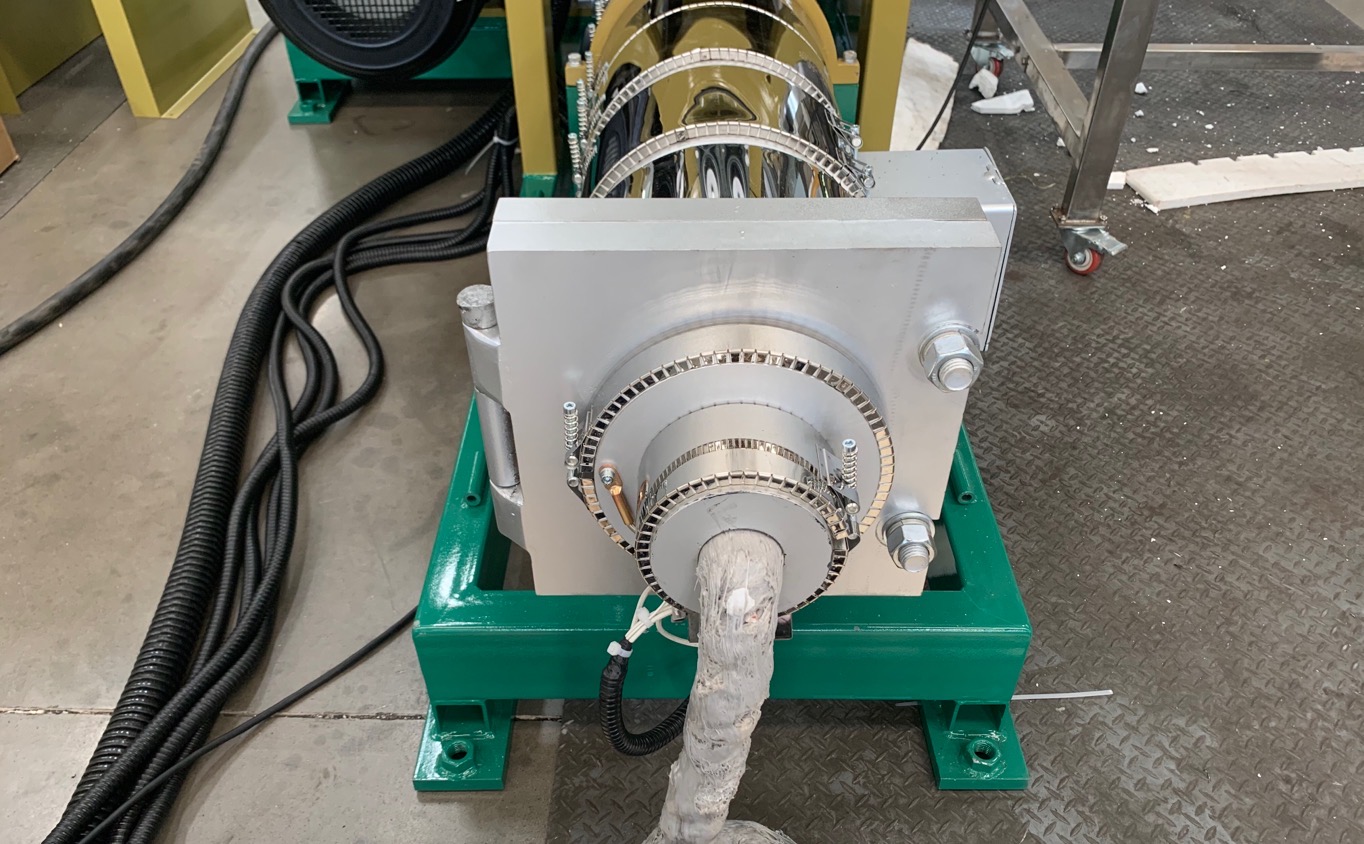

Polyethylene recycling machine

Polyethylene can be melted and remoulded into various shapes many times. This is due to its high heat resistance which allows it to retain its chemical structure even when subjected to high temperatures and turned into molten plastic. This is a very important property of polyethylene materials that can be reused and recycled, reducing the amount of plastic in the environment.

However, the number of companies offering polyethylene recycling is very limited, which results in a very low overall recycling rate. Melting and recycling polyethylene or compressed plastic is essential to avoid the incineration of polyethylene waste or placing an increased burden on its landfill.

The most common recycling methods include the reuse of polyethylene or the bonding and shredding of foamed polyethylene. Recycled polyethylene can be used as packaging material or as carpet backing for large rooms.

Why is polyethylene not biodegradable?

The term non-biodegradable is used to describe polymers that do not break down at any time during biological processes under natural and ecological conditions.Most plastics are not biodegradable because they are widely used because they are cheap, durable and versatile.

However, certain conditions can accelerate the degradation process of polyethylene. They include: moisture, oxygen, sunlight, composting and improved biodegradation by reducing hydrophobic polymers and increasing hydrophilicity.

However, it is still an environmentally friendly material as it can easily be recycled into new items such as polyethylene insulation. polyethylene recycling is a fairly simple process that involves heating it until it melts and then shaping or moulding it.

The polyethylene recycling machine is used to recycle polyethylene trimmings and rejects. It first crushes them, then melts them and turns them into pellets. These pellets can then be mixed with new material and reused in the manufacture of polyethylene products.

The polyethylene recycling machine uses a forced feeding method for a higher feeding capacity. The screw is specially designed for high extrusion capacity, stable operation and energy and labour saving.